August 30,2022

An Exclusive Look Into the World’s First 3-D Printed School

by David Stewart

Maggie Grout, the founder of the nonprofit Thinking Huts , is on a mission. With pressing educational needs and over 1.2 billion children displaced globally as a result of the pandemic, and more than 260 million children with no access to education worldwide, Grout has set out to address this critical issue. She created her nonprofit to serve underprivileged communities, and now plans to build schools out of 3-D printed material.

Humanitarian-driven technology developed by Hyperion Robotics is at the core of the technique. Grout also partnered with San Francisco–based architectural design agency Studio Mortazavi (founded by Amir Mortazavi) to create the world’s first 3-D printed school set on four acres of land off the coast of Africa, on Madagascar. While 3-D printing technology has been used for many projects of late including cars and some aspects of architecture, this will be the first full-scale school using this methodology.

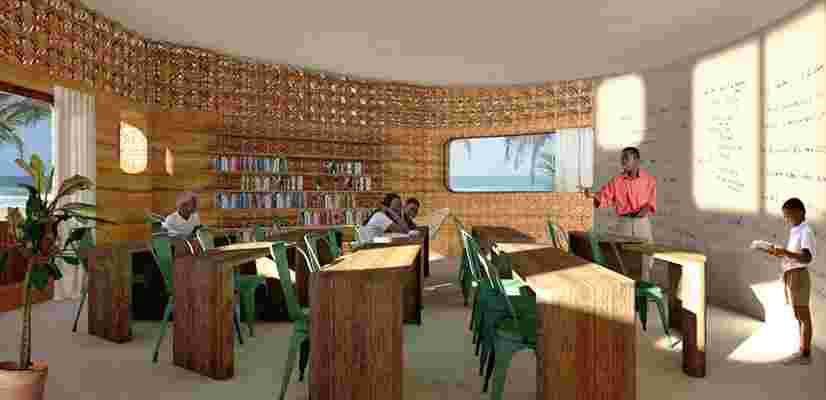

Mortazavi says that the pilot school will be built upon the university campus of Ecole de Management et d’Innovation Technologique (EMIT), located in Fianarantsoa, and will serve local Malagasy students. There will be a campus from preschool through high school for hundreds of students, with different buildings for science, libraries, physical education, music and arts classrooms, and computer laboratories. “We plan to have housing for teachers and, potentially, students,” he says.

The beehive configuration of each school allows for the attachment of multiple schools, should the campus require it.

The Design:

Simple but effective, the design features a beehive configuration that allows for the attachment of multiple schools, and also includes vertical farms and solar panels. The pilot school will consist of a hybrid design featuring 3-D printed walls and locally sourced construction materials for the roof, door, et cetera. “Pockets” on the pod walls allow for vertical farms; these also double as climbing walls for children.

Mortazavi had not taken the current COVID-19 restrictions into consideration for the design, as by the time the first school launches in the summer of 2021–22 (December to March in Madagascar), he is confident that the world will be vaccinated. If it isn’t by then, the students will be required to wear masks, and he notes that they can easily add some plexi partitions on the desks. “Plus, we have ample ventilation at the top of the walls for natural air circulation to keep the climate cool and the air refreshed,” Mortazavi says.

The schools will be outfitted with ventilation for natural air circulation to keep the climate cool while the students are in the building.

Challenges and Opportunities:

The biggest challenges included the constraints of the 3-D printing technology. “Our unique architectural relief pattern, as well as the ventilation blocks, can be fabricated by the printer,” he says. “We implemented a traditional Malagasy tribal pattern that has a repetitive stamp on both the interior and exterior of the building that we are currently testing.”

Most of the 3-D printed objects have a light gray tone as its base color, says Mortazavi, “because we want the building to be camouflaged to its natural habitat similar to how rammed-earth buildings use the pigments from the earth under the structure. We want there to be a natural graduation within the various layers of structure similar to how a rock cliff would have variations in tone.”

A pair of two-inch-thick walls spaced 8–14 inches apart give the outer shell some movement, and feature a spider web–like structure that connects them but leaves large enough voids to run plumbing and electricity throughout the building.

“The beauty of 3-D printed walls is that it’s actually easier to make curves rather than right angles. We can have walls that undulate in thickness as well as create relief patterns that with more traditional forms of construction is more challenging and expensive,” Mortazavi notes. While polygon modular pods lend a certain flexibility so the school can scale up in size based on demand, Mortazavi also remains committed to furnishing the interiors with a local aesthetic appeal, working with local craftsmen to produce furniture using sustainably harvested wood from Madagascar.

“Deforestation is a major issue in Madagascar, which holds a biodiverse ecosystem with many endemic species known only to the island. We will be making a reconnaissance trip there shortly to find the most sustainable supplier for our furniture supply in the near future when it’s possible and safe to travel there,” he says.

The exterior of each school will include a vertical garden.

Economic Impact and the Future of 3-D Design:

Thinking Huts hopes the school in Madagascar will spur innovation, while creating opportunities and access to education. “Our hybrid design is conscious of the local economy by partnering with Malagasy-based businesses, such as LafargeHolcim, as we source materials,” says Thinking Hut’s Grout. Extrapolating from the numbers, 60% of the 1.3 million primary-age Malagasy students who are not enrolled in school (assuming an aspirational student-to-teacher ratio of 35 to 1) suggests a total need of more than 22,000 classrooms. “The need for education infrastructure in Madagascar—and around the world—is enormous, and our concept is scalable as we continue to build schools with communities where they are needed most,” she adds.

The nonprofit’s goal is to have a Thinking Hut in every community where children do not have a place for education. It hopes to have a dozen printed within the first year while looking for opportunities in other countries as soon as the process and technique are fine-tuned. A campaign called Thoughtful Giving aims to raise $350,000 to support its pilot project and the next three schools.